How Much Should a Pre-Roll Cost?

Pricing pre-rolls isn’t just about slapping a number on a product and hoping for the best. For new canna-business owners, finding the right price is a balancing act that considers everything from the cost of materials to consumer expectations. The cannabis industry’s pricing is evolving, and if you’re in the pre-roll game, getting this right […]

The Science of STM Pre-Rolls: Where Tradition Meets Innovation

There’s something almost poetic about the evolution of the humble pre-roll—a product that started as a simple, hand-rolled joint and has transformed into a high-tech masterpiece. This journey is remarkable for those around long enough to remember the early days. It’s more than just a shift in how cannabis is consumed; it’s a reflection of […]

Maximize ROI with Commercial Pre-Roll Machines & Efficient Automation

Your cannabis business is booming, but the inefficiencies of manual pre-roll production are starting to bog you down. What if there was a way to enhance productivity, ensure product consistency, and ultimately boost your profits? Investing in high-quality commercial pre-roll machines could be the game-changing technological advantage you need. Let’s explore the must-have features of these machines […]

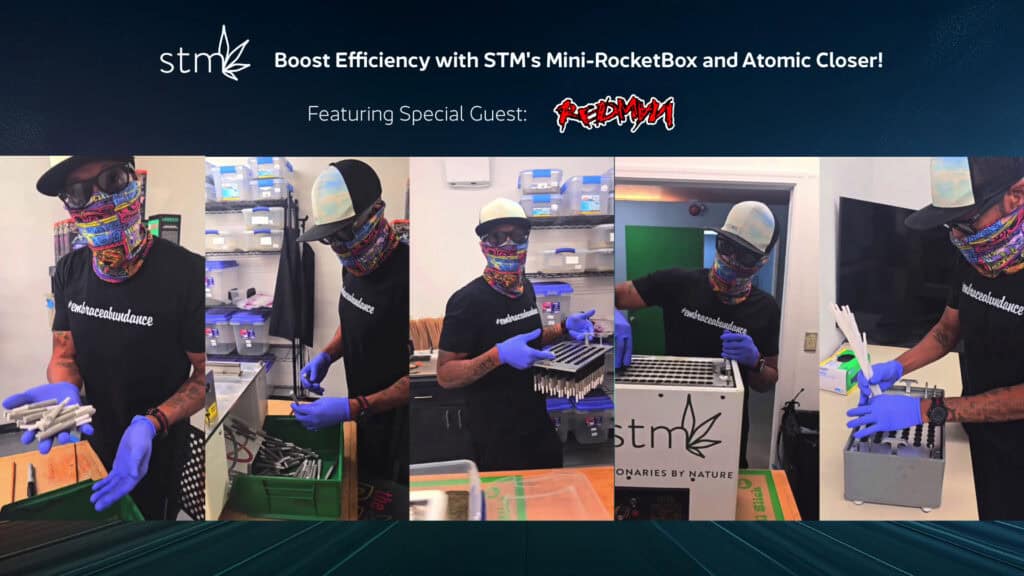

Watch Redman Dive into Pre-Roll Automation w/ STM’s Mini-RocketBox & Atomic Closer

Check out this video of rapper Redman using STM Canna’s equipment to make perfect joints and see the technology in action! In the competitive world of cannabis production, efficiency, consistency, and quality are key. STM Canna, a leader in pre-roll automation equipment, is transforming the industry with its state-of-the-art machines: the Mini-RocketBox and Atomic Closer. These […]

The Benefits of In-House Financing

As the cannabis industry grows, businesses must find efficient, cost-effective solutions to remain competitive. STM Canna, a leading innovator in pre-roll automation equipment, understands this need and is excited to announce a new in-house financing option designed to help you quickly upgrade or purchase new pre-roll automation equipment. STM Canna’s in-house financing is tailored to […]

Behind the Scenes: Our Pursuit of Pre-Roll Machine Perfection

Today, we’re taking you on an exclusive behind-the-scenes tour of STM Canna’s manufacturing department, where all the magic happens. If you’ve ever wondered how those state-of-the-art pre-roll machines come to life, you’re in for a treat. Join us as we dive into the world of precision, craftsmanship, and innovation that makes STM Canna a leader […]

STM Cannabis Grinders: A Journey of Innovation

STM Canna began with a vision to address the industry’s need for reliable and efficient processing equipment. Early products set the foundation for what would become a significant evolution in cannabis grinders and other machine technologies. First Generation: Revolution Series The introduction of the original Revolution Grinder marked a pivotal moment. This first-generation grinder improved […]

Press START To Customize Your Cones!

As the summer sun beckons and outdoor gatherings increase, it’s time to gear up for more pre-rolled joints and enjoyable smoke sessions under the open sky. To kick off this vibrant season, STM Cannabis excited to announce our Custom Cone Sale featuring fantastic introductory pricing that won’t want to miss. Throughout the entire month of […]

Modular Pre-Roll Automation: The Future-Proof Solution for Scaling Your Business

Overcome high costs, inflexibility, & the scaling limitations of popular all-in-one pre-roll systems. The pre-roll segment continues to boom within the cannabis industry. Data from Headset.io reveals pre-rolls as a consistent top-growing category, with infused pre-rolls spearheading the expansion. To meet this surging demand, cannabis producers need flexible, cost-effective, and specialized pre-roll automation solutions While […]

Grind for Greatness: Elevate Your Pre-Roll Grinding Experience w/ STM

In the grand theater of cannabis enjoyment, the pre-roll is a beloved classic – a timeless ode to convenience and craftsmanship. Yet, even classics can suffer from poor production. Picture this: you’re poised for a serene evening, pre roll in hand, ready to ascend into a cloud of relaxation, only to be jolted back to […]