You add a second shift. You add SKUs. You add new packaging formats. Then your pre-roll room starts bleeding money in places

Infuse a full tray of 72 pre-rolls in just 90 seconds. This nitrogen-free system features precise thermal dosing for liquid concentrates (distillate, live resin), eliminating the mess and inconsistency of manual injection.

Fold 72 professional Dutch Crowns in under 30 seconds. Up to 57x faster than hand-twisting, this tabletop unit eliminates "canoeing" and production bottlenecks to ensure a premium, retail-ready burn every time.

Fill 96 cartridges in under 60 seconds. This nitrogen-free, volumetric filler handles high-viscosity oils with ±1% accuracy. Built for scale, it is fully compatible with 510 threads, disposables, and custom hardware.

Legends REDMAN and Shawn Kemp could have chosen any brand of pre roll machines. But, They chose STM Canna. Watch the video to find out why.

Manual labor creates production bottlenecks and limits daily output

Inconsistent pre-rolls hurt brand quality with loose packs and canoeing

High labor costs reduce margins and slow profitability

All-in-one machines lack flexibility – can’t adapt as your operation grows.

Missed revenue from infused pre-rolls and vape carts

STM Canna has helped fill and close over 1 billion pre-rolls, eliminating these bottlenecks and helping operations fill and close over 1 billion pre-rolls efficiently and profitably.

Daily output depends on the specific machine model:

*Mini-RocketBox+: Produces up to 1,250 per hour or 10,000 per day with a small crew

*RocketBox 2.0: Produces up to 2,500 per hour or up to 20,000 per day

*RocketBox Pro: Produces up to 5,000 per hour or up to 40,000+ per day using a continuous workflow

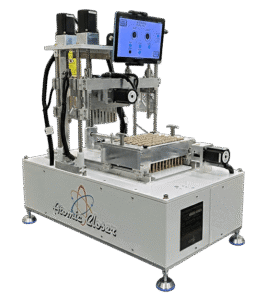

The new 2026 Atomic Closer can crown up to 34K a day

YES. A single full-time employee hand-rolling joints costs a minimum of $28,800 per year, whereas an automated machine can speed up production by 12x or more, often delivering an ROI in just 3-6 months.

Automation eliminates the “hidden costs” of manual labor, such as production bottlenecks and inconsistent pack quality

All RocketBox models use STM’s proprietary nitrogen-filled airbag system, not mechanical tamping like KnockBox or King Kone. This creates an even, fluidizing vibration that fills cones without gaps, while the adjustable lift plate ensures proper density at the filter and volumetric metering via the top tray delivers consistent, accurate target weights.

STM machines are compatible with standard 70mm Dog Walker, 84mm (1-1/4″), 98mm (Special Small), and 109mm (King Size). Other types sizes available on request.

The Mini-RocketBox+ is up to 5× faster than the Knockbox (143 joints in <45 seconds vs. 100 joints in 2 minutes). It uses volumetric metering with no pre-weighing to automatically hit target weights, while Knockbox users often must pre-weigh material or manually fix under-filled joints.

STM’s proprietary nitrogen-filled airbag system replaces simple mechanical tamping for more consistent fills.

Built from American stainless steel and aluminum and manufactured in Spokane, WA, the Mini-RocketBox+ is domestically made—unlike the overseas-produced Knockbox.

Top brands choose modular systems to avoid downtime. If an “all-in-one” machine (like JuanaRoll) is expensive, complicated and if something breaks, the entire production line stops.

With STM’s One-Tray Workflow, stations are independent; if the filler is being cleaned, the closing and infusing stations can keep running, ensuring continuous output at a fraction of the cost.

For more details on this read the blog post Analyzing All-In-One Systems.

Demos are available on a case-by-case basis. If you would like a demo, reach out here to schedule a demo.

STM proudly leads by example in customer service, support and satisfaction.

Our highly regarded Client Success Program includes: a dedicated client portal with a range of tools, videos and support documents; a dedicated Client Services representative tasked with providing you technical assistance, virtual training, and in-depth support; and options for On-Site Training.

A One Year Parts & Labor Manufacturing Warranty is included with every machine. We design, engineer and manufacturer our equipment in-house to uphold the utmost quality. As such, new part orders would be ordered from STM directly vs. having to source 3rd party parts overseas or from external manufacturers.

If you’re rolling for personal consumption, you can purchase a pre-rolled joint already filled with ground cannabis or use an empty cone to fill and pack your joint manually. For commercial production, many dispensaries and cannabis processors prefer a pre-roll machine, such as the Mini-RocketBox for efficiency and product consistency.

Payment for all orders is due in full. We offer financing through our partner NEC. We may have other terms and plans available. Contact us.

Yes. STM has a Trade-In Quote program for customers looking to upgrade from older machines. Contact us for more information.

Compare STM Equipment to Futurola and Integrated Machines

| Feature | STM Modular | Futurola | All-in-One |

|---|---|---|---|

| Production Capacity | Up to 5,000 pre-rolls/hour | 800-1,000/hour | 1,000-3,500/hour |

| System Design | Modular, scalable build-as-you-go | Compact | Fixed, integrated unit |

| Repair Downtime | Short (we are the manufacturer) | Moderate (if you can get parts) | Long |

| Upgrade Cost | Low to moderate | Low to moderate | $150K+ |

| Training Time | 1 hour per machine | 1-2 hours | Full days to weeks |

| Fill Adjustability | Highly adjustable, precise layered fills | Moderate adjustability | Limited adjustment options |

| Footprint | Full system fits 10' x 10' room | Small area | Requires dedicated production area |

| Packing Technology | Volumetric + weight-based | Inefficient tamping | Standard vibration only |

| Vibration Power | High-power for consistent, dense packs | Limited Low/Hi | Various types |

| Maintenance | Low maintenance, fast cleaning | Moderate maintenance | Complex, costly & time-consuming |

| Operator Requirements | No specialized skills needed | Basic training required | Specialized training required |

| Downtime Risk | Modular design minimizes impact | Moderate impact | Single failure stops production |

Not sure which system fits your operation?

Talk to a Pre-Roll Specialist*Comparison information gathered to the best of our ability. STM Canna is not responsible for inaccuracies or changes to competitor specifications.

Ditch the slow, inconsistent, and costly methods. STM Canna delivers the automation edge your pre-roll operation needs.

Automated Fill & Close – Output up to 50,000 pre-rolls per day .

Precision Pack Quality – Consistent density, crowned finishes, zero canoeing

Lower Labor Costs – Replace 6 to 8 manual staff with one efficient system

Modular, Scalable Design – Start with what you need now, expand as you grow

Made in the USA, Built to Last – Easy to clean, simple to maintain, built for ROI.

We live and breathe pre-rolls. Dive into our articles to see how STM Canna is redefining automation for cannabis producers.

You add a second shift. You add SKUs. You add new packaging formats. Then your pre-roll room starts bleeding money in places

Price drops hit fast. Labor, rent, and compliance costs stay flat. That gap is where margins die. Modular pre roll machines win

Faster machines do not always increase profitability. Many operators buy a cannabis rolling machine, thinking it will solve labor issues. Six months

You’ve stumbled onto our comprehensive guide into the fascinating world of pre-roll sizes and paper types! STM Canna is proud to present

In some cases, pre roll automation can cut labor costs by $250,000 per year. That number gets attention fast. If you run

Your pre-roll team does not lose margin on filling speed. They lose it on cleanup, changeovers, and the fixes that stack up

A $25-per-hour operator hand-closing pre-rolls for four hours a day costs you $2,200 a month. Two operators cost $4,400. It doesn’t feel

Pre rolls drive steady sales in almost every store. They fit value packs, premium drops, and everything in between. Multi-packs, infused SKUs,

Two names come up more often than not when you are looking to buy a pre roll filling machine. King Kone and

"Managing two Mini's and an Atomic Closer, we can do 10,000 infused pre-rolls a day!" - Ryan Ratzloff, CEO of Lion Labs