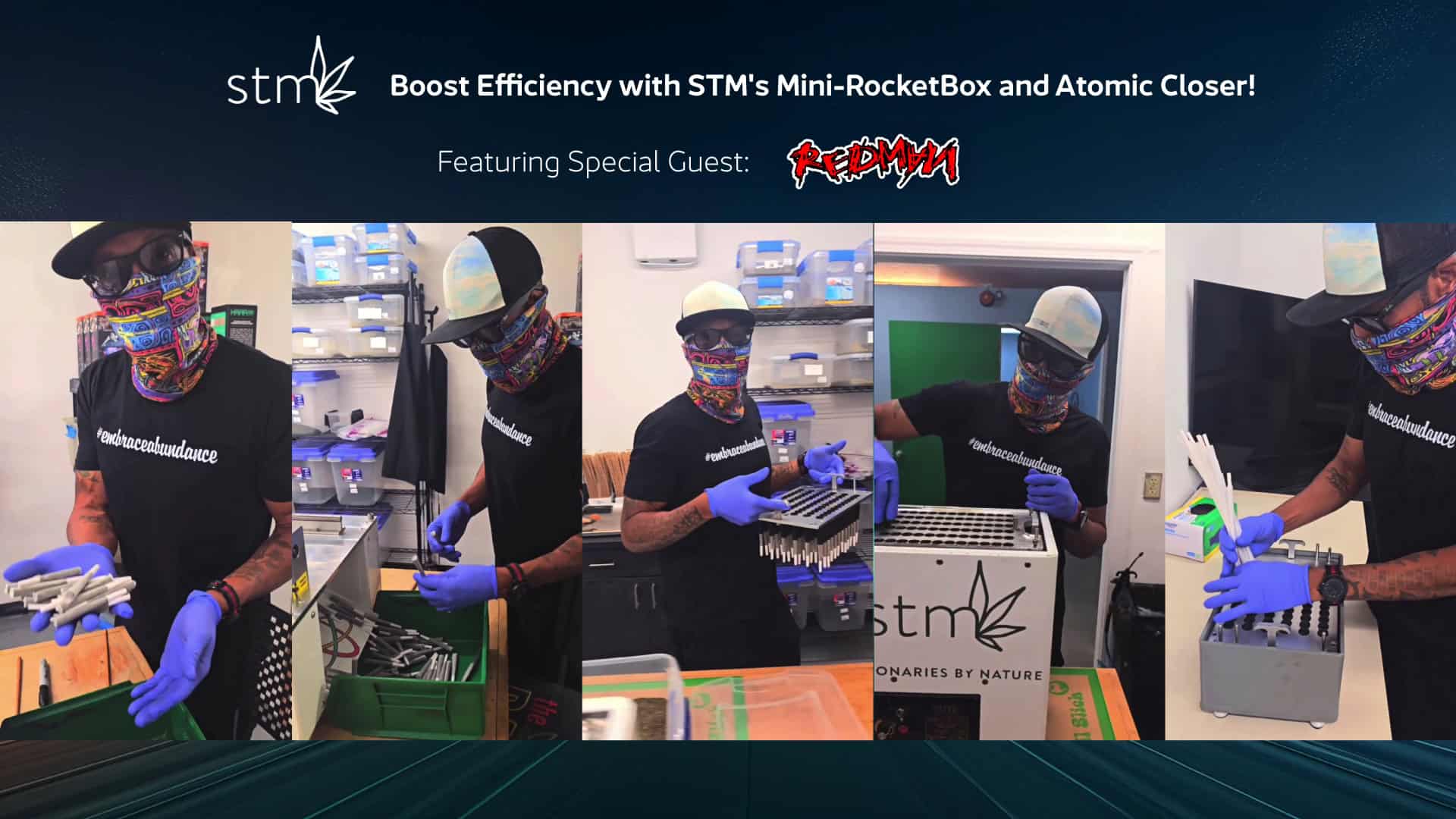

Check out this video of rapper Redman using STM Canna’s equipment to make perfect joints and see the technology in action!

In the competitive world of cannabis production, efficiency, consistency, and quality are key. STM Canna, a leader in pre-roll automation equipment, is transforming the industry with its state-of-the-art machines: the Mini-RocketBox and Atomic Closer. These innovative machines are redefining joint production’s speed, accuracy, and cost-effectiveness standards.

The Mini-RocketBox: Fast, Accurate, and Easy to Use

The Mini-RocketBox is a powerful, compact machine for high-speed, consistent pre-roll production. It can fill up to 72 pre-rolls per 45-second cycle, dramatically reducing production time compared to manual methods. Its user-friendly interface ensures quick setup and minimal training, making it an ideal choice for businesses aiming to optimize their operations.

The standout feature of the Mini-RocketBox is its modular design. Adding more modules can quickly expand your production capacity as your business grows. This scalability makes it a cost-effective solution for small and large cannabis businesses.

The Atomic Closer: Perfect Pre-Roll Finishing Every Time

After filling, the Atomic Closer ensures that each pre-roll is perfectly closed. This machine guarantees uniformity and prevents product loss, maintaining high quality in every joint. Designed to integrate seamlessly with the Mini-RocketBox, the Atomic Closer creates an efficient, automated production line from filling to finishing. It can close a tray of 72 joints every 40 seconds, boosting production speed and efficiency.

With Atomic Closer, businesses can achieve high-quality standards while significantly reducing labor costs. Automating the closing process eliminates the need for manual intervention, saving time and minimizing the risk of human error.

Modular Advantages: Flexibility and Scalability

One of the most significant advantages of STM Canna’s pre-roll automation equipment is its modular design. This flexibility allows businesses to adapt their production lines to meet changing demands. Whether you need to increase capacity or integrate new technologies, STM Canna’s modular systems provide the adaptability you need.

The modular design also ensures that maintenance and upgrades are straightforward and cost-effective. Individual modules can be serviced or replaced without disrupting the entire production line, minimizing downtime and keeping operations running smoothly.

Save Time and Reduce Costs with Pre-Roll Automation

Automating your pre-roll production with STM Canna’s equipment significantly reduces manual labor. Automated processes translate to direct cost savings and let your team focus on other critical business tasks. Increased efficiency means you can meet production targets faster, respond quickly to market demands, and boost your output without compromising quality.

STM Canna’s Mini-RocketBox and Atomic Closer are at the forefront of pre-roll automation. Their ability to produce high-quality joints quickly and efficiently, combined with the modular design offering scalability and flexibility, make them essential tools for any cannabis production facility. By saving time and reducing labor costs, these machines enhance productivity and set new benchmarks in the industry. As the cannabis market grows, STM Canna’s cutting-edge solutions lead the way in streamlined, efficient, high-quality pre-roll production.

Explore the future of pre-roll automation with STM Canna and elevate your cannabis production today.