Overcome high costs, inflexibility, & the scaling limitations of popular all-in-one pre-roll systems.

The pre-roll segment continues to boom within the cannabis industry. Data from Headset.io reveals pre-rolls as a consistent top-growing category, with infused pre-rolls spearheading the expansion. To meet this surging demand, cannabis producers need flexible, cost-effective, and specialized pre-roll automation solutions

While all-in-one pre-roll machines are a relatively recent solution, their high costs, limited adaptability, scaling challenges, and lack of integrated infusion capabilities create problems for many businesses.

STM Canna, a seven-year industry veteran, is revolutionizing pre-roll production with modular automation systems designed for unmatched versatility, cost-effectiveness, operational ease, and their unique one-tray workflow.

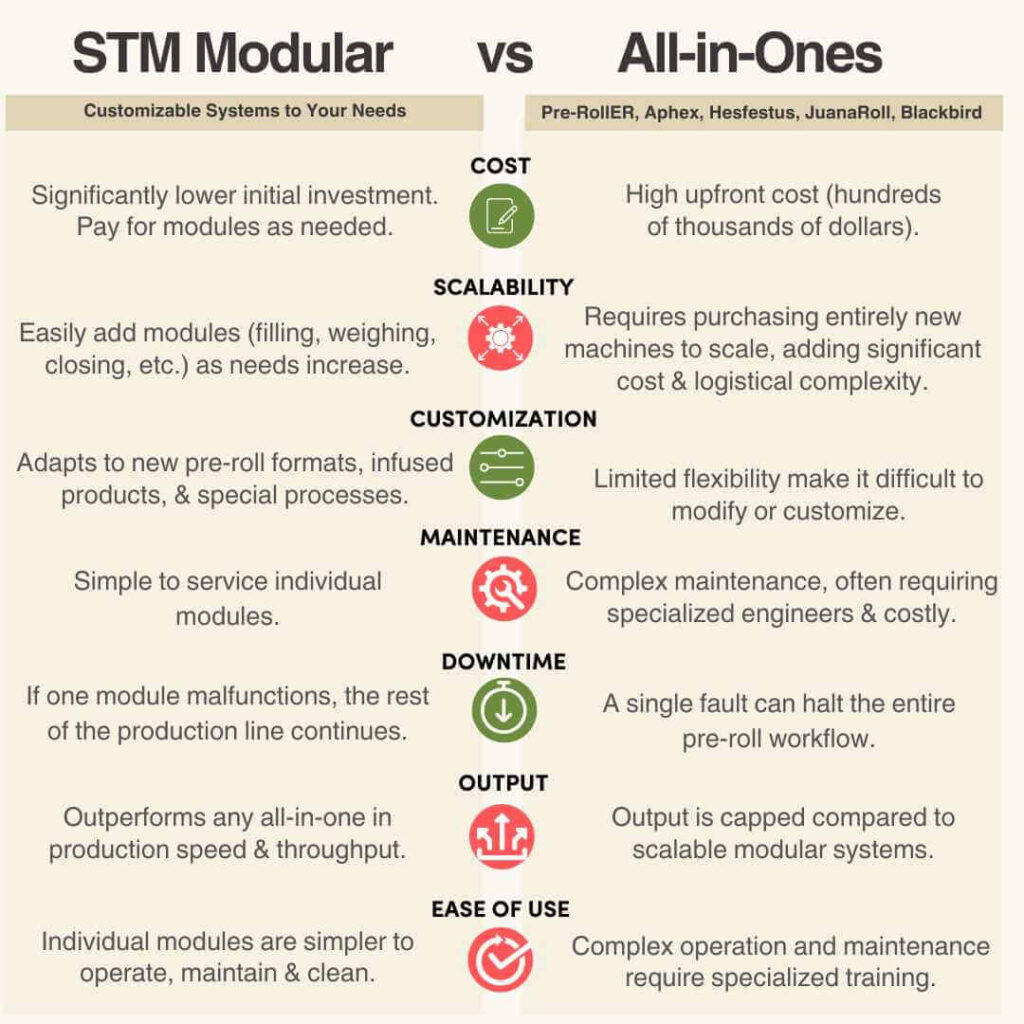

Modular vs. All-in-One: Key Differences

All-in-one pre-roll machines aim to streamline production by consolidating filling, tamping, weighing, and twisting into a single unit. While this seems convenient, these machines have significant drawbacks:

- High Costs (and Affordable Options): All-in-one systems are capital-intensive, frequently costing hundreds of thousands of dollars – a major investment for many cannabis businesses. STM Canna offers accessible solutions like their popular Jump Starter 2.0 System, featuring a Mini-RocketBox Plus pre-roll filling machine and the Atomic Closer finishing machine for just $49,000. Easily add more modules as you grow and expand.

- All-in-ones are inflexible: Making it challenging to adapt them for new products, formats, or specialized pre-roll techniques. STM Systems are flexible and offer multiple joint tray sizes to accommodate your evolving needs.

- Limited Infusion Options: All-in-one solutions either don’t offer infusion capabilities, or provide inefficient infusion methods that don’t match the quality or speed of dedicated infusion machines. The STM Canna Astro Infuser module is the fastest, self-contained pre-roll infuser capable of infusing 3600 an hour.

- Maintenance Woes: Their complex design makes maintenance difficult, often requiring specialized engineers and expensive air systems. A single module failure can shut down your entire pre-roll production.

- Scaling Difficulties: Expanding production with all-in-ones often means buying completely new machines, creating logistical and financial strain.

STM Canna’s modular approach overcomes these challenges. Their systems break down the pre-roll process into discrete stages, with specialized machines for each step, all utilizing their innovative one-tray workflow. This offers outstanding benefits:

Cost-Effectiveness, Scalability, and Quality Control

Modular systems allow for strategic investment. Start with essential modules and expand as your product line and business scale. Easily integrate specialized modules as you explore the infused pre-roll market. This approach promotes financial flexibility and supports long-term growth without massive upfront costs.

Unmatched Versatility, Customization, and Infusion Excellence

STM Canna’s modular systems, one-tray workflow, and flexible tray sizes empower producers to adapt quickly. Introduce new pre-roll sizes, explore infused options, or integrate specialized techniques. Stay ahead of market trends and consumer preferences without replacing your entire pre-roll automation setup.

Ease of Use, Cleaning, and Maintenance

Individual modules are less complex than massive all-in-one machines. This leads to simpler operation and faster training for new employees. Cleaning and maintenance are streamlined, with technicians focusing on specific modules rather than dismantling integrated systems. STM’s one-tray workflow ensures minimal interaction at each stage, simplifying the process.

Operational Resilience for Uninterrupted Production

If an issue arises within one module in an STM Canna system, other modules keep working. This minimizes downtime and protects production continuity. With all-in-one systems, a single fault can halt your entire pre-roll workflow.

Unrivaled Production Output with Automation

STM Canna’s modular systems are designed for maximum production. Their high-capacity modules, including the Astro Infuser, RocketBox Pro, and Atomic Closer, seamlessly integrate to deliver outputs surpassing any all-in-one pre-roll machine. Industry leaders using STM Canna systems achieve upwards of 60,000 pre-rolls daily – proof of modularity’s power.

The STM Canna Advantage: Future-Proof Your Pre-Roll Operation

STM Canna‘s shift towards modular pre-roll automation, along with their one-tray workflow and seamless integration of solutions, drives unmatched cost savings, flexibility, ease of use, and output. As the cannabis industry becomes even more competitive, the benefits of modular systems are undeniable.

To explore STM Canna’s advantage, contact a sales rep at https://stmcanna.com/contact/ or schedule a demo via https://stmcanna.com/live-demo/