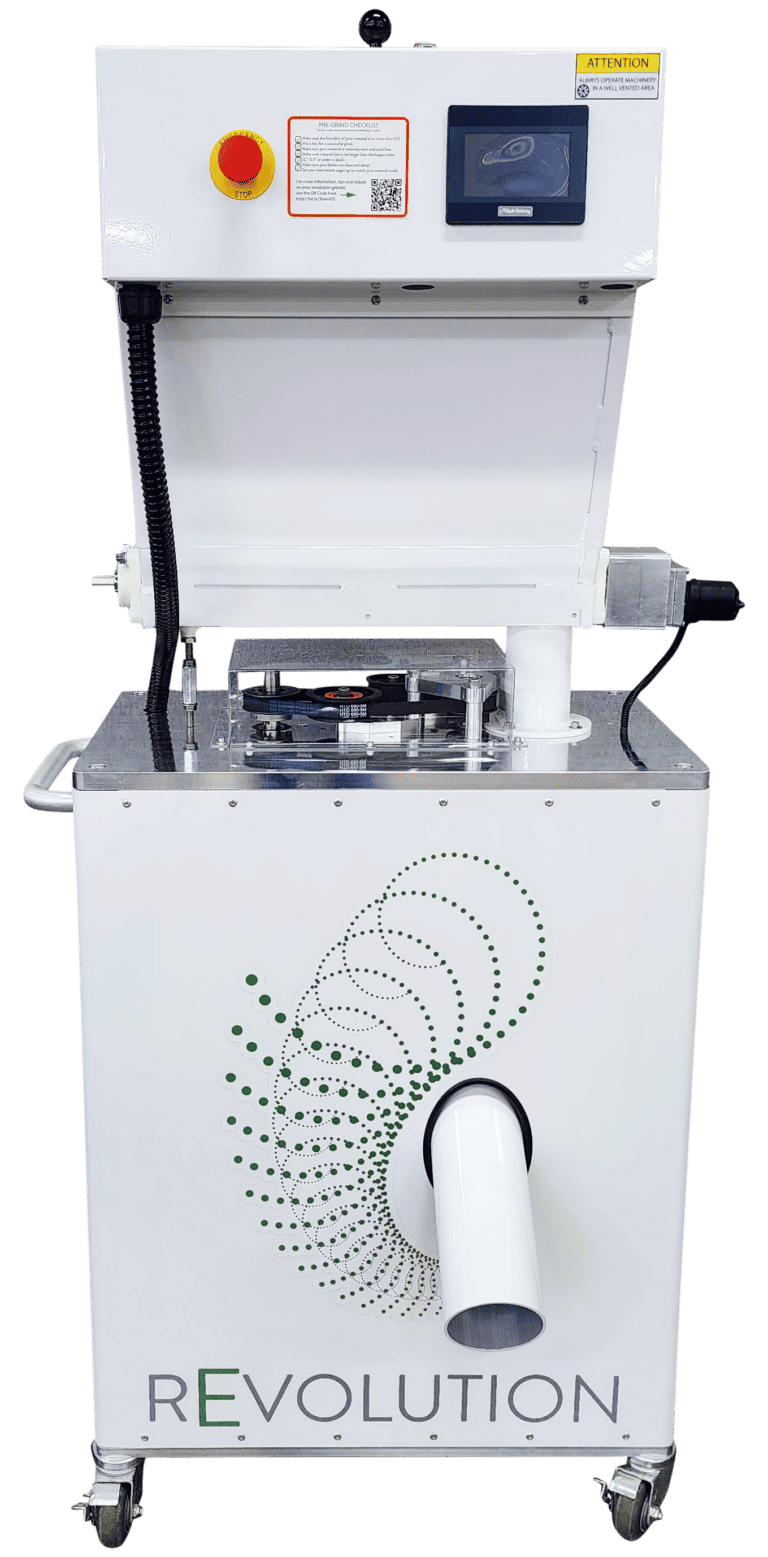

Elevate your cannabis processing with the patented Revolution 2.0 commercial cannabis grinder. Preserve terpenes & cannabinoids. The #1 grinder for perfect pre-rolls backed by science.

*For 60 months, OAC. Contact our sales team for more information.

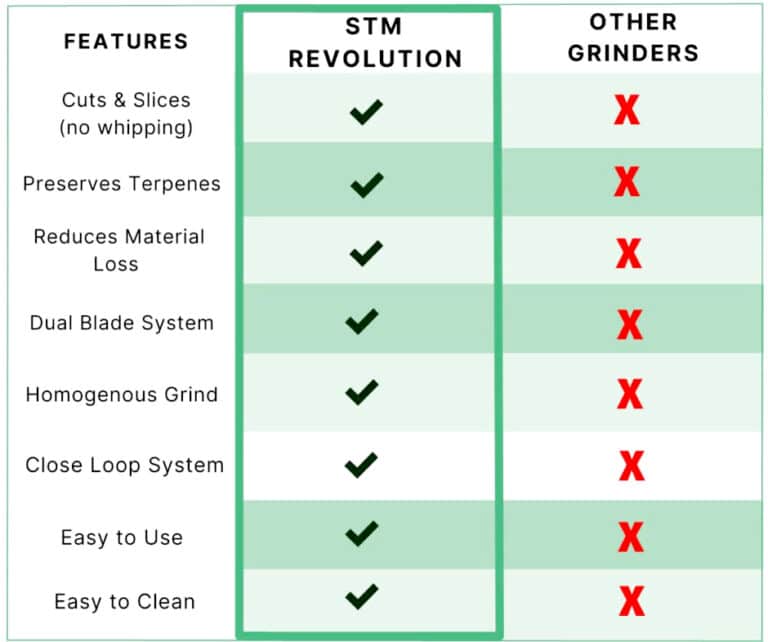

Our Revolution 2.0 Commercial Cannabis Grinder is the key to preserving terpenes and cannabinoids for potent and consistent pre-rolls. No whipping, no mashing, just a precise, homogenous grind with a dual blade system which carefully cuts and slices like scissors.

An independent 2021 study by Brilliant Health LLC validates the Revolution 2.0’s low-heat, low-friction grinding approach with less than 1% terpene loss.

"The Revolution Grinder is the only one good enough for Ice Box Flat Farms Pre-rolls"

Pat- IBFF, CA

The Revolution 2.0 commercial cannabis grinder guarantees superior yields, cutting like scissors up to 35+ lbs or more of dry flower/hemp per hour – ideal for premium pre-rolls and extraction. Our patented dual-blade system delivers consistent particle size that mills and whips can’t match and doesn’t destroy or obliterate precious terpenes and cannabinoids.

"Machine is fantastic, efficient and fast. Much better than Futurola."

Jim, Grass Roots

This mini powerhouse of a commercial cannabis grinder can fill and pack a tray of up to 143 joints in 30-60 seconds. The adjustable top tray allows for fine-tuning, compensating for under or overfills. Thanks to Lift Plate Technology, cones level from the bottom for an even fill. No pre-weighing; dump and go.

Embrace efficiency, precision, and quality with STM Canna’s One-Tray Automated Workflow. Our unique system seamlessly integrates the steps of pre-roll production, from grinding, loading, and packing, to weighing and closing with a Dutch crown finish. We offer machines, extensive training, and ongoing support to ensure consistent excellence in your output. Ready to scale? STM Canna’s innovative solutions adapt to your growth, propelling your cannabis venture to new heights. Your success is our mission.

Whether you need a complete cannabis pre-roll system or individual components, our modular designs adapt to your growth needs. Join the exclusive league of cannabis producers trusting STM Canna for pre-roll automation needs.

STM Canna

Resources

Email: sales@stmcanna.com

Sales: 509-800-4187