Faster machines do not always increase profitability. Many operators buy a cannabis rolling machine, thinking it will solve labor issues. Six months

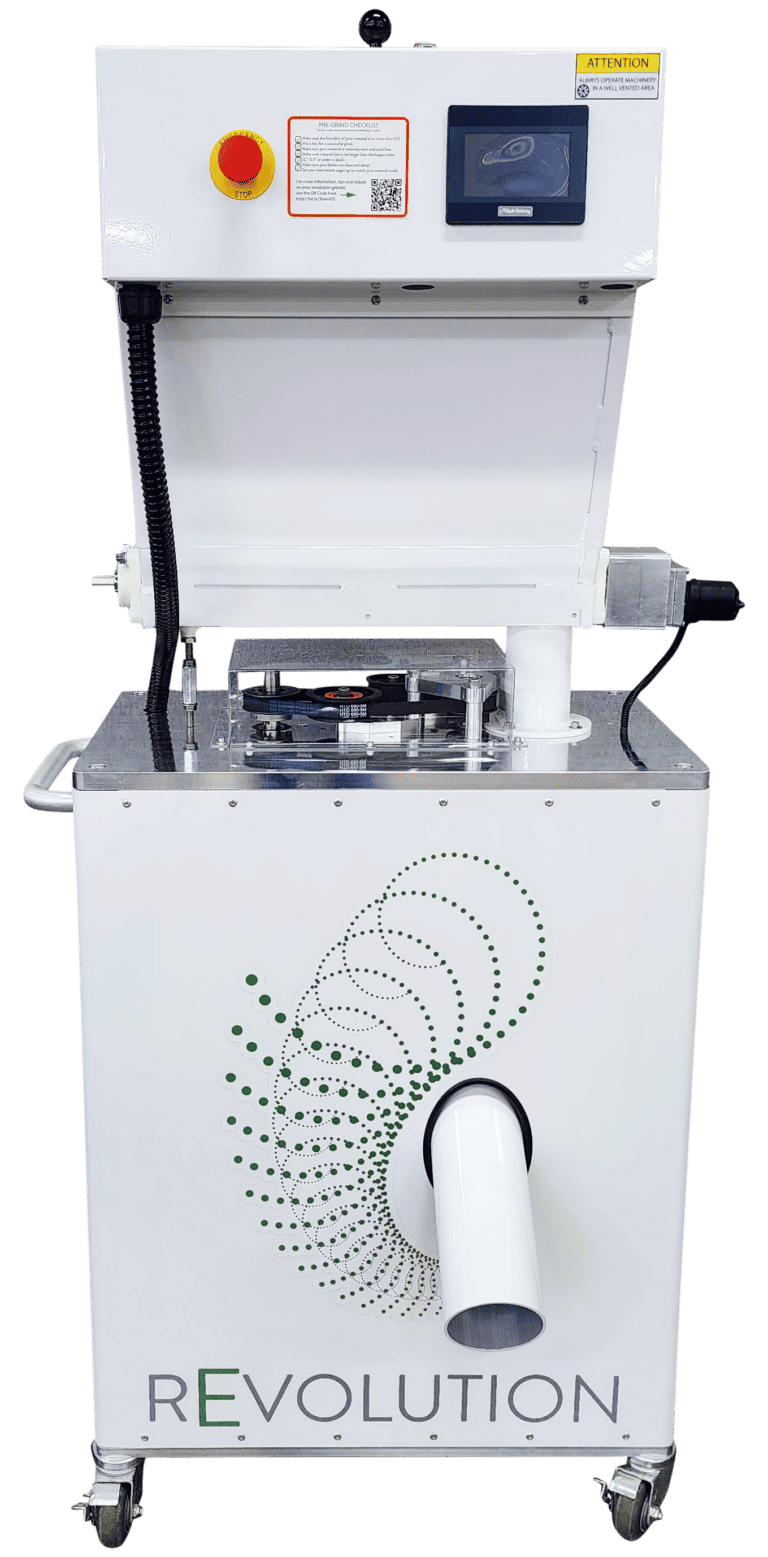

Keep terpene-rich flower intact with patented Scissor-Cut dual-blade processing. Produce a consistent pre-roll grind at 30+ lb per hour while limiting heat buildup and resin smear. Made in the USA with food-grade stainless steal

High-Output Precision: Industrial Performance Without Compromise.

Eliminate production bottlenecks with the first machine in our one-tray workflow automation, the only commercial cannabis grinder engineered for continuous operation and maximum cannabinoid retention.

Industrial Velocity: Process up to 400 lbs of flower daily. Designed to replace teams of manual labor with a single, high-efficiency workstation.

Operator-First Safety: Fully enclosed 304 Stainless Steel housing with an OSHA-compliant, multi-point safety interlock system.

Intelligent Throughput: A self-regulating, closed-loop system monitors motor load in real-time to prevent clogs and mechanical downtime automatically.

From Zack Powers of Quickies Pre-Rolls to Hip Hop Legend REDMAN, the biggest names in the cannabis game choose STM Canna cannabis equipment. Check out the video to find out why!

This grinder is built for real throughput in a licensed facility, not a back-room batch process.

Run it as a continuous-feed step ahead of cone filling, weighing, or extraction prep.

Typical operating numbers operators plan around:

Throughput: 15 to 30 lb per hour with flower at 7 to 10% moisture

Daily output planning: up to 400 lb per day with the right upstream staging

Power: 220V, 18 amps

Motor: 3 HP industrial motor

Construction: 304 stainless steel, food-grade contact surfaces

Screens: interchangeable fine and coarse options

Feed: continuous hopper

Discharge: industrial chute for bins or direct handoff to your tray workflow

Engineered for high-volume pre-roll production, the Revolution 2.0 delivers a clean, consistent grind that preserves terpenes, cannabinoids, and trichomes. No smashing. No heat damage. Just precision cutting for better burn, better flavor, and better yield.

How It Works

Continuous Feed System: A large hopper feeds dry flower (7–10% moisture) for nonstop industrial grinding.

Precision Auger Control: Touchscreen-controlled auger delivers steady, repeatable material flow.

Dual-Blade Cutting Technology: Stainless steel blades slice cannabis like scissors and never crush to protect terpene content and structure.

Interchangeable Particle Screens: Dial in uniform fine or coarse grind sizes optimized for pre-rolls or extraction.

Self-Regulating Anti-Clog Design: Closed-loop system detects resistance, reverses blades, and clears buildup automatically-maximizing uptime.

Clean, Efficient Discharge: Vibrated chute moves finished grind smoothly into collection bins.

Proven Performance

Independent testing confirms <1% terpene loss thanks to low-heat, low-friction grinding- ideal for premium pre-roll manufacturing.

Built for scale. Designed for consistency. Trusted for industrial cannabis grinding.

Your filler can only run as fast as your grind stays consistent.

A common pattern looks like this: your cone filler runs clean for 20 minutes, then grind density shifts, tamp pressure changes, and you start pulling cones for rework. One person ends up babysitting the line.

Revolution 2.0 is designed to sit in a pre-roll manufacturing chain where grind feeds a weigh step and then a cone filling machine. It supports steady output so your downstream equipment keeps pace.

Best-fit production environments:

Automated pre-roll lines

Cone filling machines and tray workflows

Cannabis weighing systems

MSO production floors running multiple SKUs

Large cultivation processing rooms

Extraction prep when you need predictable particle size

White-label pre-roll manufacturers running tight turnarounds

Heat is the quiet margin killer. It drives off volatiles, changes stickiness, and pushes resin into places you do not want it.

Low-speed slicing helps keep heat down versus impact milling, and it reduces trichome damage that turns into dust and loss on screens, gloves, and room surfaces.

What operators can expect:

Better aroma consistency across a batch

Less “flat” flavor on premium SKUs

More stable burn rate because the grind stays uniform

Less fines-driven harshness in the first third of the cone

Audits punish sloppy equipment choices. So do sanitation logs.

Revolution 2.0 uses food-grade stainless construction and an enclosed grinding chamber with safety interlocks aligned with commercial facility expectations. It is built for regulated North American environments where inspection readiness matters every week, not once a year.

Compliance-facing build points:

304 stainless steel construction

Enclosed chamber design

Safety interlocks for operator protection

Industrial electrical components suitable for commercial installs

Fast sanitation access to support documented cleaning intervals

Here’s the grinder ROI question you can answer in one shift. What does one cone reject cost you?

Use this line-level formula:

Daily reject cost = (cones rejected per day) x (grams per cone) x (cost per gram) + (rework labor hours) x (loaded wage)

Example numbers most teams recognize:

10,000 cones per day

2% rejects from airflow issues equals 200 cones

1.0g per cone, $1.20 per gram internal cost equals $240 material

2 hours rework at $28 loaded wage equals $56 labor

Total: $296 per day, about $6,512 per month on a 22-day schedule

That is one failure mode tied to grind consistency. The same grinder also hits uptime, sanitation labor, and downstream jam rates.

What is the best commercial cannabis grinder for pre-roll production?

The best choice holds particle size, limits fines, and stays easy to clean at your target throughput. A scissor-cut style grinder is built around those priorities. This is the Revolution 2.0 in a nutshell.

How many pounds per hour can Revolution 2.0 process?

Operators plan around 15 to 30 lb per hour, with flower moisture in the 7 to 10% range.

Can it run hemp and CBD flower?

Yes. The grinder is used for both THC and CBD workflows in commercial processing settings.

What moisture level runs best?

Most high-throughput rooms target 7 to 10% moisture to keep grind stable and reduce smearing.

Does it need special electrical?

Plan for 220V power with appropriate amperage and a commercial install that matches your facility standards.

"The Revolution Grinder is the only one good enough for Ice Box Flat Farms Pre-rolls" - Pat- IBFF, CA

1. Disassemble

Retract the push rod, remove the front plate, and loosen fasteners to access blades and screens.

2. Degrease

Soak components in food-safe degreaser with hot water for 15–30 minutes, then rinse clean of plant resin.

3. Disinfect

Wipe all surfaces with 99% isopropyl alcohol. Do not scrape components.

4. Dry

Rinse once more with clean water, then air dry or use compressed air.

5. Reassemble

Reinstall all parts, securing bolts and quick-release tabs before operation.

1. Choose desired speed (low/med/high) for auger system and (low/med/high) for blade system. Initiate Start/Stop on the touch screen control panel before adding material into the hopper, where the auger system will then begin to pull the material down into the blade area.

2. Material is cut by proprietary, highly polished stainless steel serrated blades before falling through 1 of 2 interchangeable particle screens.

3. As material reaches the optimal size and exits the screen, the anti-clog agitator creates vibrations which push the final product down and out the chute for easy collection into a bin below.

Heat and friction may occur in the case of a clog but would not generally apply in standard use due to the application of a lower RPM. Many competitors do operate at a significantly high RPM (upwards of 25,000-37,000 RPM) where temperatures can begin to evaporate and cause damage to highly valuable terpenes and cannabinoids.

The ideal size of a particle or bud for use in the STM Revolution is 2″ inches or less. Because the throat of the hopper is around 3″ inches in diameter, pieces entering the machine larger than 2″ inches may cause clogging or a blockage in the system.

The STM Revolution machine in its entirety is not UL Listed, however, all parts and components of the machine are all OSHA compliant and listed under various listings. Please feel free to review the STM documentation on the Revolution 2.0 Cannabis Grinder here.

STM Canna takes safety very seriously. While a machine itself cannot be GMP (Good Manufacturing Practices) certified, our machine is GMP compliant. We follow strict standards to meet OSHA compliance and use only the highest quality, commercial-grade components.

For operator safety and efficiency, the STM Revolution is fully enclosed in 304 Stainless Steel and is very effective in limiting particulates from being spout outside of the machine. The material enters through an enclosed hopper and then cycles through the system without any place for exposure before exiting the chute and directly into a collection bin.

Please also note that our system does not pulverize the material in a way that knocks off a heavy amount of trichomes – which otherwise could create lots of kief and upends more particle ‘dust’ into the air. We recommend using a 27-gallon collection bin with a lid to place under the chute (hole may be cut into the bin equal to the size of the chute to have the bin remain fully enclosed as well).

The STM Revolution is equipped with both a hopper and chute for a continuous feed, however, the throughput depends on the quality and the moisture level of your material as well as nug and stem size.

The unit may process up to 400 lbs of flower daily. Please view this video for important information on material preparation – Revolution Grinder Pre-Prep.

The STM Revolution cuts and slices material with precision, whereas whipping/milling blasts the trichomes off of the plant with force. An analogy would be using scissors to cut something vs. thrashing or whipping something around to break it down. Movement is slower to lessen friction and heat.

The Revolution is constructed of 304 Food-Grade Stainless Steel. Technical documents and information can also be found here in the STM Products Dropbox folder.

The machine is GMP compliant but not certified.

The STM Revolution plugs into a 220v receptacle. Technical documents and information can be found here in the STM documentation section of our website.

Explore our latest articles to learn more about cannabis machinery and production.

Faster machines do not always increase profitability. Many operators buy a cannabis rolling machine, thinking it will solve labor issues. Six months

You’ve stumbled onto our comprehensive guide into the fascinating world of pre-roll sizes and paper types! STM Canna is proud to present

In some cases, pre roll automation can cut labor costs by $250,000 per year. That number gets attention fast. If you run

Your pre-roll team does not lose margin on filling speed. They lose it on cleanup, changeovers, and the fixes that stack up

A $25-per-hour operator hand-closing pre-rolls for four hours a day costs you $2,200 a month. Two operators cost $4,400. It doesn’t feel

Pre rolls drive steady sales in almost every store. They fit value packs, premium drops, and everything in between. Multi-packs, infused SKUs,

Two names come up more often than not when you are looking to buy a pre roll filling machine. King Kone and

Pre rolls sit at the center of modern cannabis manufacturing. Demand keeps rising. Margins keep tightening. Manual filling no longer fits serious

Preroll sales keep climbing. Demand rarely slows. Production teams feel the pressure first. Orders stack up. Labor is stretched thin. Downtime becomes

"Machine is fantastic, efficient and fast. Much better than Futurola."

Jim, Grass Roots

This mini powerhouse of a commercial cannabis grinder can fill and pack a tray of up to 143 joints in 30-60 seconds. The adjustable top tray allows for fine-tuning, compensating for under or overfills. Thanks to Lift Plate Technology, cones level from the bottom for an even fill. No pre-weighing; dump and go.

Embrace efficiency, precision, and quality with STM Canna’s One-Tray Automated Workflow. Our unique system seamlessly integrates the steps of pre-roll production, from grinding, loading, and packing, to weighing and closing with a Dutch crown finish. We offer machines, extensive training, and ongoing support to ensure consistent excellence in your output. Ready to scale? STM Canna’s innovative solutions adapt to your growth, propelling your cannabis venture to new heights. Your success is our mission.

Whether you need a complete cannabis pre-roll system or individual components, our modular designs adapt to your growth needs. Join the exclusive league of cannabis producers trusting STM Canna for pre-roll automation needs.

| FEATURES | STM REVOLUTION |

OTHER GRINDERS |

|---|---|---|

| Cuts & Slices like Scissors (no whipping/mashing) |

✓ | ✗ |

| Preserves Terpenes (low temp/friction) |

✓ | ✗ |

| Reduces Material Loss |

✓ | ✗ |

| Dual Blade System | ✓ | ✗ |

| Homogenous Grind | ✓ | ✗ |

| Close Loop System | ✓ | ✗ |

| Easy to Use | ✓ | ✗ |

| Easy to Clean | ✓ | ✗ |