In 2023, commercial pre-roll machines have greatly benefited both small and large cannabis producers alike.

As we transition into this next year, we want to provide an updated guide so you can reevaluate your pre-roll machine options. Automated pre-roll machines have revolutionized cannabis production, transforming it from a labor-intensive exercise to an efficient, cost-effective operation.

Say goodbye to the days of employing an army of manual laborers. With today’s technologically advanced commercial pre-roll machines, achieving high-volume production has never been easier.

From filling 50 to 500 pre-rolls in one go, these power-packed cone filling machines are time-savers and investment goldmines, typically offering an ROI in mere weeks.

From early pioneers like the Futurola Knockbox 100, to newer cutting-edge models like the Rocketbox 2.0, the quality and efficiency of pre-roll machines have been improving year after year.

Business Verticals for Compact Pre-Roll Machines

- Smaller Cannabis Producers: Ideal for boutique, low-volume runs.

- Retail Dispensaries: For in-house joint production.

- Mid-size Production: For larger but more specific runs.

Choosing the Right Commercial Pre-Roll Machines for 2024

For the businesses of tomorrow, the Rocketbox 2.0 and our Mini-RocketBox Plus+ remain flagship models, epitomizing durability, efficiency, and high ROI.

2024 is a year in which we’ll likely see additional machines enter the market to cater to various commercial demands, including heavy-duty production requirements.

Price Considerations: Digging Deeper into Costs

When evaluating the price tag of commercial pre-roll machines, the scope should extend beyond the upfront cost. Small-scale machines may initially range from $1,500 to $8,000, but this often covers only base packages.

Add-ons and system upgrades, such as advanced sensors for weight adjustments or software enhancements for better user interface, warranties & support, can all contribute additional costs significantly – depending on the machine producer’s business model.

Therefore, when budgeting for your ideal machines, you’ll want to consider the entire lifecycle cost, including maintenance, upgrades, and energy consumption.

Please note that there are basically two primary “tiers” of pre-roll machines in the market currently. Three if you consider personal pre-roll machines for the home user who wants to roll their own. We think these are more like “rolling devices” more than modern “machines”, but we digress.

First, you have the more basic models with lower production capacity (typically 50 to 100 hundred pre-rolls per cycle), and then you have large industrial grade systems capable of handling more than 10,000 joints a day. STM Canna is proud to offer machines from both categories.

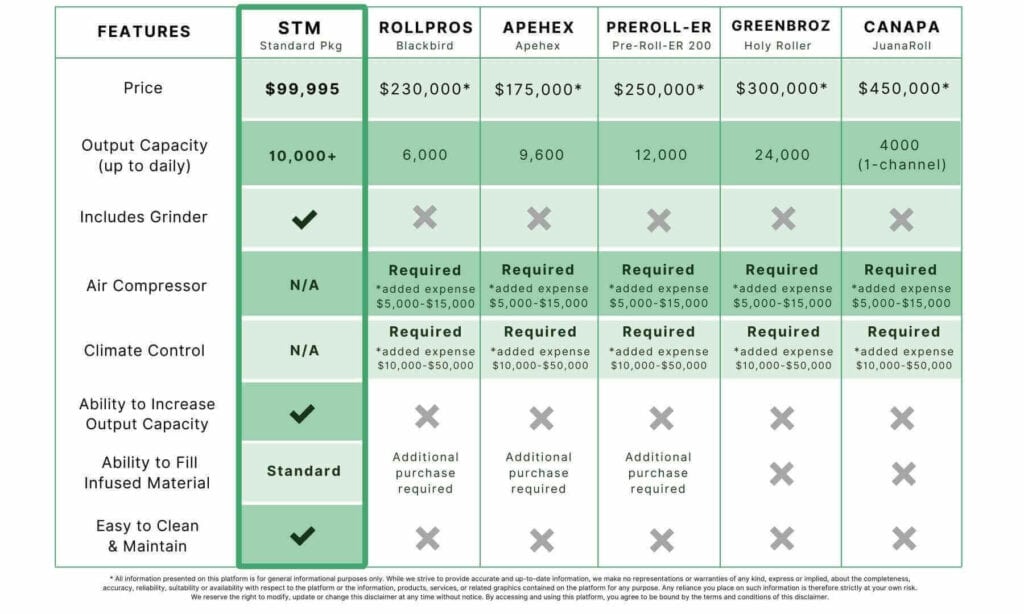

As you can see from the image above, some of our competitor’s commercial pre-roll machines have an initial investment of $300,000 to $400,000! Although they may operate at a similar pace and scale to our machines, some of them have a massive physical footprint as well (you’ll need some space to accommodate them)!

Other machines may require additional changes to your physical space such as adding climate control, or needing to install a dedicated air compressor. STM Canna designs our machines to be simple but effective so you don’t have to worry about these issues with us!

We try to cater to both ends of the pre-roll production market. You shouldn’t need a million dollars to get started with your pre-roll production system.

Beyond the Basics: a Glimpse Into Functionality

Modern commercial pre-roll machines have evolved into engineering marvels. The focus is on high-precision preroll cone filling mechanisms that vary from automated tray-loading systems to fine-tuned vibration controls.

The Mini-RocketBox Plus is a trailblazer with its Lift Plate, which levels your cones from the bottom up for a more even fill. Little extras like this help to improve accuracy and minimize product loss, making the filling process almost surgical in its precision.

Growing Need for Speed + Accuracy

If efficiency and speed top your checklist, it’s hard to overlook what the Mini-RocketBox Plus offers. It can fill an astounding 143 pre-rolls in 60 seconds or less, setting a standard for the industry. Compare that with the Futurola Knockbox, which can only output 100 pre-rolls in 2 minutes!

But it’s not just about speed; our machines boast amazing accuracy – especially when you pair them with our Launchpad pre-roll scale – a pivotal factor in many markets with stringent pre-roll weight regulations. This machine should be your go-to option when your operation demands a bit lower volume, but you still need to retain high precision.

Quality Joints: The Art of Precision

The quality of the joint is the endgame in pre-roll production, and modern machines leave no stone unturned here. Factors like the type of paper used, the grind size of the cannabis, and the filling precision all contribute to this. Selecting premium quality papers and optimizing grind sizes ensure the user’s smoking experience will be exquisite.

Getting the perfect grind size is an art and a science. A too-fine grind could lead to overfilling and restricted airflow, while a too-coarse grind may create air pockets, resulting in an uneven burn.

STM’s Revolution cannabis grinders stand out by employing low heat and low friction technologies, thus ensuring that the grind size is always optimal for a perfect pre-roll.

Pre-Roll Technology: What to Expect Next Year

As the cannabis industry barrels into 2024, innovation shapes the pre-roll machine landscape. Anticipate newer models of commercial pre-roll machines to possibly feature enhanced AI capabilities for optimized filling and packing, further minimizing human error.

This surge in tech-powered features is not just a mere upgrade; it’s a revolutionary step in achieving the finest pre-roll quality and uniformity. From sensor-based weight adjustments to quality control algorithms, 2024 aims to redefine what it means to own high-quality commercial pre-roll machines.

Sustainability Through Pre-Roll Machines

It’s no longer just about speed and efficiency; sustainability is also a buzzword as we edge closer to 2024. Manufacturers increasingly use eco-friendly materials and energy-efficient mechanisms in their commercial pre-roll machines.

Not only does this reduce the carbon footprint, but it also amplifies the brand’s commitment to sustainable cannabis production. From energy-efficient motors to using recycled metals and plastics, the commercial pre-roll machines of tomorrow are set to be as green as the cannabis they help roll.

Pre-Roll Machines & Regulatory Compliance

As regulations around cannabis products continue to tighten, compliance becomes a cornerstone for any business in this sector. The Mini-RocketBox Plus already offers accuracy levels that make it easier to meet stringent regulatory requirements.

However, 2024 will likely bring machines up to speed with built-in compliance features, such as real-time weight validation, track-and-trace systems, and automated or remote reporting capabilities. These will enhance productivity and simplify regulatory adherence, saving time and potential legal complications.

Future of Customization w/ Commercial Pre-Roll Machines

Customization is key in meeting diverse consumer needs, and the commercial pre-roll machine industry is catching on. 2024 is expected to usher in more machines capable of handling various papers and filters (ours already handle most popular paper brands and sizes!) and offer multiple filling and packing styles. The latest trend is in creating infused pre-rolls.

This level of customization enables cannabis producers to cater to niche markets, thereby increasing brand appeal and revenue.

Imagine machines that can produce CBD and THC pre-rolls, switch between hemp and rice paper, or even add a hint of natural flavors — from one tray to the next in an organized system.

Investing for the Future

With so much innovation on the horizon, choosing future-proof commercial pre-roll machines becomes an important task. Brands like STM Canna are leading the charge with models like the Rocketbox 2.0 and Mini-RocketBox Plus+. We set the gold standard when it comes to reliability, efficiency, and adaptability.

Perhaps it’s a good time to reevaluate your industrial pre-roll machine needs? We’re seeing rapid changes in technology, consumer preferences, and regulatory landscapes, so staying ahead of the curve is not just an option; it’s a necessity. Let’s swap out your older machines for STM’s industry leading pre-roll solutions.

If Something Goes Wrong, How is the Support?

Another often overlooked element of owning commercial pre-roll machines is the simple question, “How much support will I receive after the sale?” With highly complicated or overly complex all-in-one machines, if one piece of that machine goes down – your entire pre-roll production line goes down.

However, with our patented one-tray workflow, STM’s machines are paired together in an assembly line formation to negate the chances of a failure with one component affecting the rest of the operation.

If an all-in-one machine goes down, not only are they difficult to access/fix in some cases, but if you don’t have a warranty, we expect you could pay fairly hefty support costs.

STM offers many additional warranty options and support plans to care for you well after the sale.

We’ve also been rated as one of the top cannabis companies to work for in 2022!

A Final Word

As we usher in 2024, the Mini-RocketBox Plus remains a frontrunner, offering unparalleled efficiency, speed, and ROI. Supported by a one-year warranty and a dedicated client service team, it’s the indisputable champ for those businesses looking to begin optimizing their cannabis pre-roll production processes.

Stay ahead of the curve with cutting-edge technology, and maximize your cannabis production potential in 2024! Join our mailing list or follow us on Twitter to get notified when our new offers drop.